Within PIRO Fusion’s production process, a casting tree (CT) is a container of multiple job order items. As each Job Order can have several items with the same design but possibly made out of different metals, these items are typically assigned to one or more Casting Trees so that they may be cast. A CT is made up entirely of a single metal or master alloy. Each CT is made up of the items needed to be cast and the trunk (also called the sprue).

During the production process, users are prompted either to create new CTs, usually when a service reaches the “Casting tree building” service, or to assign a JO to an existing CT, if an eligible CT is available. There are several actions that can be performed when creating and routing CTs, or when modifying CT attributes. These actions can be performed using the buttons displayed above and below the grid.

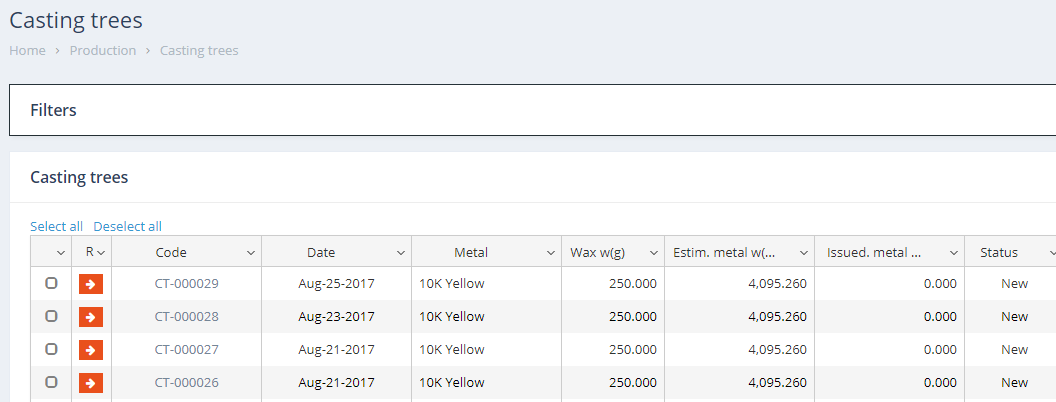

A casting tree is much like a job order: it contains certain production-related data and also includes items and services. This tool allows viewing, adding and managing CTs and also provides CT filtering options.

The CT grid displays information about all existing CTs, which is neatly organized into rows and columns. The following columns and information is displayed on the CT grid:

- Code: displays the CT’s unique code.

- Date: displays the date assigned to the CT.

- Metal: displays the type of metal used for casting the CT.

- Wax w/(ozt/g): displays the wax weight in OZT or g (Gram) of the CT.

- Estim. Metal weight (ozt/g): displays the estimated metal weight needed for casting the CT.

- Issued metal weight (ozt/g): displays the metal weight in OZT or g that was issued for casting the CT.

- Status: displays the current status of the CT.

- R. good w(ozt): displays the total weight of goods in OZT or g that were returned after casting the CT.

- R. to inv. W(ozt/g): displays the total weight in OZT or g that was returned to the inventory after casting the CT.

- Thickness: displays the thickness of the CT

- Casting Temp (° C): displays the temperature in degrees Celsius needed to be reached for casting the CT.

- Flask Temp (° C): displays the flask temperature in degrees Celsius needed to be reached

- Notes: displays the notes that were assigned to the CT.

- Loss weight (ozt/g): displays the total weight in OZT/g that was lost while processing the CT.

- Loss %: displays the weight in percentages that was lost while processing the CT.

- Items: displays the names of the items assigned to the CT.

- Casting batch: displays the code of the casting batch to which the CT is assigned.

- Processing service: displays the service that the CT is currently in.

- Created by: displays the full name and username of the user who created the CT order.

Searching for specific CTs can be done using the expandable Filters panel located above the CT grid. The following filters are available:

- CT code: filters based on the CT’s unique code.

- Hide finished casting trees: if checked, CTs in ‘Finished’ status are not shown.

- Date from / to: filters based on the CT date. A specific date interval can be specified.

- Status: filters based on the status of CTs.

- Job item code: filters based on the CT items’ ‘Ref. item code’, containing job item code.

- Metal type: filters based on the metal type of the CT.

- Casting batch code: filters based on the code of the casting batch to which CTs have been assigned.