Casting alloys are produced from pure metal(s) and optionally one or more other alloy elements. Casting alloys are the raw materials for casting.

Viewing casting alloys

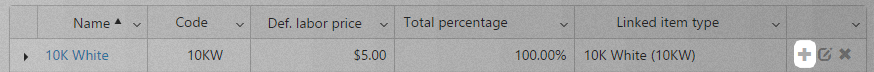

On the Casting Alloys subtab the casting alloys added to PIRO Fusion will be displayed in a list. The columns of the list show the following information:

- Name: Displays the name of the casting alloy.

- Code: Displays the unique code that identifies the casting alloy in the system.

- Def. labor price: Displays a default price of the labor required by the casting alloy (it can be defined on the Casting alloy details form).

- Total percentage: It adds up the ratios of the components and it should display 100% when all the components have been added to the casting alloy.

- Linked item type: As it has been mentioned above, when a metal type is created in PIRO Fusion a corresponding item type is automatically added to the Item types management menu, so the settings and functionalities of item types can be applied to metals as well. The Linked item type column displays the name of this corresponding item type under Item types management.

By clicking on the sign next to the name of a casting alloy, a sub-list will be expanded including the components of a particular target metal and their relevant properties:

sign next to the name of a casting alloy, a sub-list will be expanded including the components of a particular target metal and their relevant properties:

- Name: Displays the name of a particular component.

- Type: Displays whether the component is a pure metal (Metals) or an alloy (Alloys).

- Code: Displays the unique code that identifies the component in PIRO Fusion.

- Ratio: It shows how many percent of the casting alloy is made up of a particular component.

Adding/editing casting alloys

If you add (with the Add button under the item type’s grid or ![]() icon) or copy (with the Copy button or

icon) or copy (with the Copy button or ![]() icon – the Copy button is available only when a casting alloy is selected) or edit (with the

icon – the Copy button is available only when a casting alloy is selected) or edit (with the ![]() icon) a casting alloy, the Casting alloy details form will open.

icon) a casting alloy, the Casting alloy details form will open.

On the Main settings section you can specify the basic properties of the casting alloy:

- Name: The name of the casting alloy can be entered in this field.

- Code: The unique code that will identify the casting alloy in the system can be entered in this field.

- Default casting temp.: The default casting temperature of the casting alloy can be specified in this field.

- Default labor price: A default price of the labor (like casting) assigned to the casting alloy (in the Labor item type field) can be specified in this field. The drop-down will display the items of the item group with an SKU of “Labor”.

- Labor item type: A labor type (like casting) required by the casting alloy can be selected in this drop-down field.

- Default button weight: The user can specify in this field the default button weight of the casting trees casted from this particular casting alloy.

- Description: A custom description can be added to the casting alloy in this text-field.

On the Casting temperatures section you can specify the casting temperatures required to obtain different thicknesses of the casting alloy.

The casting temperatures can be specified for the following three thicknesses:

- Medium

- Thin filigree

- Thick and Heavy

When a particular thickness is selected on a casting tree (in the Casting tree menu) the metal casting temperature will be automatically uploaded (if available).

Adding components to a casting alloy

After a casting alloy has been created in PIRO Fusion its components and their ratios (applied during mixing) can be specified. This can be done by using the ![]() icon which is at the end of casting alloy’s row.

icon which is at the end of casting alloy’s row.

The Casting alloy item details form will open where the following information can be specified related to a particular component of the casting alloy:

- Metal group: As it was mentioned above the components used to mix a metal type may belong to two groups in PIRO Fusion: pure metals, casting alloys. In this drop-down the user can select the group that includes a particular component.

- Metal type: The component can be selected in this drop-down. Only those metal types will be shown in the list that are included by the group selected in the Metal group drop-down.

- Ratio: In this field you can specify what percentage of the target metal is made up of a particular component.

- Track on invoice customer balance: If this is checked, the casting alloy components can be used in particular reports.