This is a transformation tool that mixes master alloys from the metals and alloys available on stock. The tool also checks whether the needed mixing metals are available on the inventory in sufficient quantities.

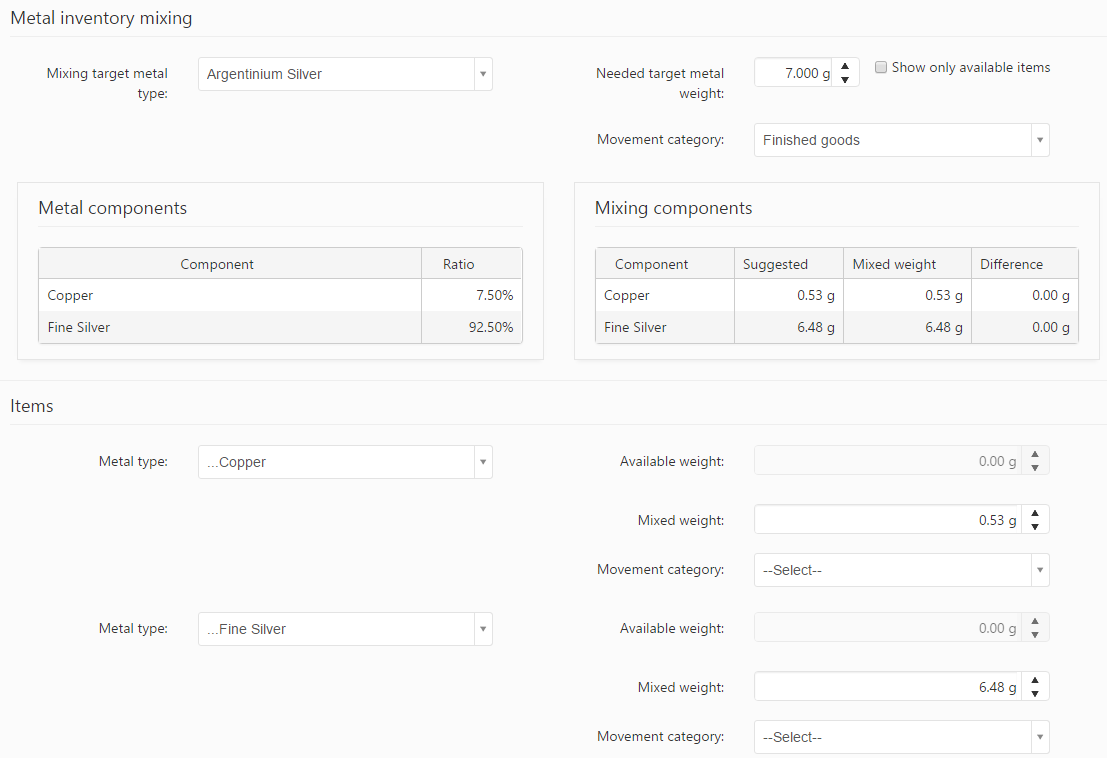

- Mixing target metal type: Specifies the metal needed to be obtained.

- Needed target metal weight: Specifies the quantity of the target metal, expressed in grams. Once the mixing has been finished, the target metal will be added to the inventory in the specified amount.

- Show only available items: If checked, displays only the metals which are available on the inventory.

- Movement category: specifies the metal movement category from the predefined list of movement categories.

There are two additional sections on the form: Metal components and Mixing components. After selecting the target metal type, its components are displayed in the Metal components section. Their ratios, specifying the required component proportions in the target metal, are also displayed here.

The Mixing components panel is filled in automatically after selecting the metal types in the Items tab.

To obtain the suggested metal amount, the metal types used in the mixing of the target metal need to be defined. These metal types should be identical to the ones displayed in the Metal components section. When defining the mixing components, the following information must be specified:

An additional option is only available if the Enable customer inventory mixing admin setting is active. This setting may be found in ![]() Administration →

Administration → ![]() Admin settings → Inventory settings

Admin settings → Inventory settings

- Mix from customer inventory: if checked, the metal component will be removed from the customer’s inventory instead of the company’s inventory. The Customer field also becomes available, where the customer may be specified from the customer list.

- Metal type: The component metal type can be selected from the drop-down list. If the component is coming from a customer’s inventory, the list contains only the customer’s inventory items.

- Available weight: Displays the metal component’s available amount.

- Mixed weight: Sets the mixed weight, the metal component’s weight that is used and added to the alloy. After selecting the metal type, the mixed weight is displayed in the Mixing components section. PIRO Fusion calculates and suggests the metal amount needed to obtain the target metal weight. The suggested weight greatly helps define the mixed weight.

This value is also displayed in the Mixing components section. If it differs from the suggested amount, the difference is also displayed in the Mixing components grid. - Movement category: Specifies the outgoing movements category (e.g scrap, powder, finished goods, etc.).

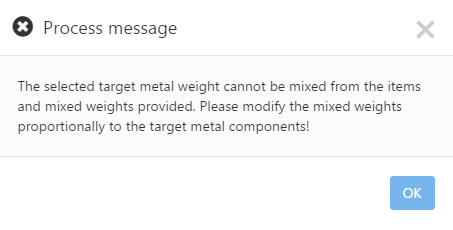

If the Mixed weight differs from the suggested amount, PIRO Fusion displays a warning message:

The Total mixed weight displays the resulting weight based on the entered Mixed weight . If the component mixed weight is not the same as the suggested metal weight, the total mixed weight will not match the target metal weight.

If the total mixed weight is less or more than the needed target metal weight, PIRO Fusion displays the Suggested alloy amount. The mixed weights should be altered until the total mixed weight is equal to the target metal amount, and the suggested alloy amount displayed is 0.

The component quantities used in mixing the target metal are removed from the inventory after clicking on Process on inventory. At the same time, the metal obtained from the mixing is added to the inventory.